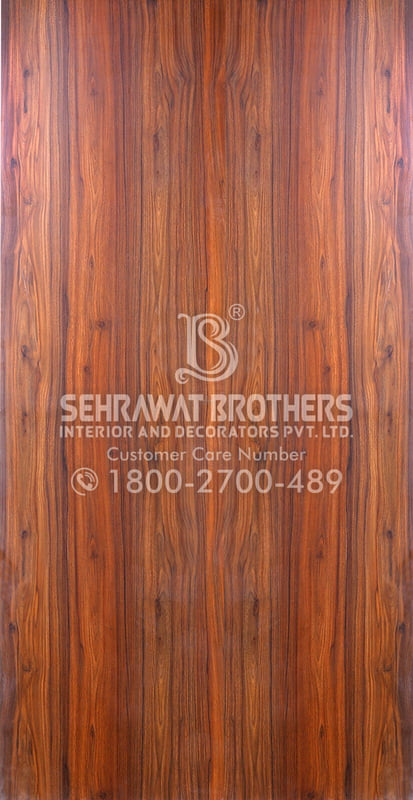

High-Pressure Laminate Sheet SBHPLS9005

HPL is produced by saturating multiple layers of Kraft paper with Phenolic resin. A layer of printed decor paper is placed on top of the Kraft paper before pressing. The resulting sandwich is fused together under heat and pressure. Because Phenolic and melamine resins are Thermoset plastics, the curing process transforms the resin into plastic by a cross linking process that converts the paper sheets into a single, rigid laminated sheet. Thermo setting creates strong, irreversible bonds that contribute to its durability. High pressure laminate is laminated to a composite panel utilizing a variety of adhesives. Consistent and economical foundation. Due to its durability, high pressure laminates are a common choice for horizontal surfaces including flooring, counter tops and desktops.

Size: 48" X 96" (8 X 4 Feet)

Thickness: 6 mm

Common Uses for High Pressure Laminates

- Cabinetry

- Tabletops

- Case Goods

- High Pressure Laminate Flooring

- High Pressure Laminate Furniture

- Counter tops